Australia’s population is continuing to age. But, as a result of this, the need and demand for aged care are continuing to grow year after year. With more aged care facilities starting up in the country and demand higher than ever, aged care owners are facing the challenge of managing their patients, the demands of stakeholders and linen and laundry management requirements day in and day out. Therefore, all sectors must be managed effectively to guarantee that all patients receive the highest level of care while also being free from the threat of dangerous microorganisms and cross contamination from soiled linen or dirty linen.

The following blog will explore one of the most important aspects of cleanliness and sanitisation in aged care facilities; laundry management. It will then showcase how staff can manage this as effectively as possible to secure the highest level of cleanliness and care.

Laundry management requires so much more than how clothes, linen and towels are washed. While a good washing machine is essential to ensure materials are left as hygienic as possible, all aspects of laundry management must be considered to guarantee that patients, staff and guests are protected against harmful bacteria.

For this reason, laundry management must begin before the linen is even changed. It starts when staff are loading clean linen onto our collapsible X-Carts or Linen Cube Trucks. This is because many factors can come into play to cause a build-up of microbes from this step onward, such as improper material handling, dirty hands or cross-contamination with dirty linen.

To ensure the spread of pathogens is limited, staff must have access to the right laundry management equipment, including clean PPE and cleaning cart accessories, such as linen bags, to prevent soiled laundry from coming into contact with clean supplies. In addition to this, the right settings such as temperature and cycle length should be used to ensure microbes are gone. Using a laundry guide can assist achieve the best results.

Laundry management also doesn’t stop when clean linen is taken out of the dryers. It also requires effective linen storage in cupboards and dry storage areas to prevent the spread and contamination of microbes.

Over time, even the best staff can become negligent. This may be due to cutting corners to complete jobs faster, or it could be the result of them forgetting the correct procedures. Training the most competent staff regularly is one of the best ways to guarantee that they always handle linen and laundry management effectively.

Owners of aged care facilities can also make an additional effort to dedicate team leaders in laundry areas. These leaders are the staff members who are the most competent and skilled in their area. They can be charged with training other staff, but they can also oversee the processes to guarantee that staff, patient and guest safety is prioritised.

For those aged care facilities seeking in-depth training regarding laundry management in aged care, Rubbermaid offers countless online training modules.

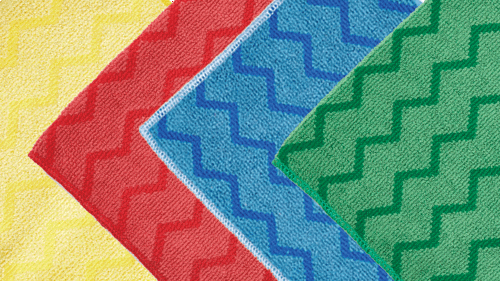

Implementing a colour-coded system is a simple yet effective way to prevent contamination and reduce the risk of cross contamination. Using different coloured bags or bins for various types of linen—such as bedding, towels, aprons, and patient clothes—helps staff easily identify soiled items versus clean linen, streamlining the laundering process and supporting infection control procedures.

Rubbermaid Commercial Products recommends assigning colours for specific tasks: for example, red for heavily soiled or used linen that may contain body substances, blue for general dirty linen, and green for clean linen ready for distribution in patient care areas. This helps staff separate and immediately place items in the correct bin or leak proof bag, minimising the spread of pathogens across the facility.

It may seem tempting to mix sheets and HYGEN Microfibre Cleaning Cloths in a load to reduce cleaning time. Doing this, however, is a risk of cross-contamination. This is because the dirt and bacteria from each material can cross during the washing process. Above this, different materials in the wash together can also prevent items from cleaning properly by limiting movement. This is why it is important to separate items such as woollens, which may stop items from spinning as required in the wash.

Washing in categories can provide the best chance for all bacteria to be eradicated from materials.

Staff in aged-care facilities must also be mindful that there is an elevated chance that bodily fluids could end up on sheets and towels. Keeping an eye out for this and washing any items that are soiled with bodily fluids separately is also an extra barrier against the spread of infection.

Monitoring and tracking linen usage is a vital part of effective linen and laundry management in aged care facilities. It helps prevent the loss or theft of linen and identifies any issues related to supply and demand. Additionally, tracking can inform staff when linen should be discarded or recycled—especially used linen that is showing signs of wear such as holes, tears, or thinning materials. These damaged items can become breeding grounds for bacteria and increase the risk of infection for aged care residents.

Implementing smart systems like barcoding or RFID technology provides valuable insights into linen circulation across the facility. Rubbermaid Commercial Products recommends using such systems to monitor the movement of linen in real time, ensuring that handling soiled linen, clean linen, and inventory levels are always under control.

Proper tracking supports laundry services and commercial laundry providers by making sure items are returned to the right departments. It also enhances efficiency and contributes to the overall cleanliness and safety of patient care areas.

At Rubbermaid Commercial Products, the team understands that linen management is a complex ecosystem. Therefore, the team is always happy to help so you can manage your linen as effectively as possible.

Contact them today to discover how you can improve your aged care linen management today.